ENVIRONMENTAL CUSTOM CABLE ASSEMBLIES

Case Study – Environmental Custom Cable Assembly

The Challenge

Build a custom cable assembly for a manufacturer of energy management systems.

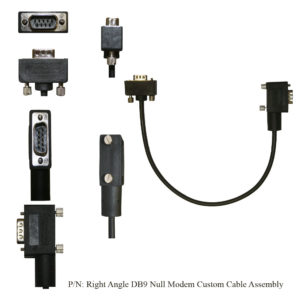

A client who manufactures systems that monitor and manage energy quality and power consumption came to Compatible Cable with a custom cable assembly requirement. For their new product line, they needed to connect two systems via a null modem cable with a custom pin out. Because of the tight space in the design, one end of the cable needed to be a horizontal right angle DB9 connector with only one thumbscrew.

The Solution

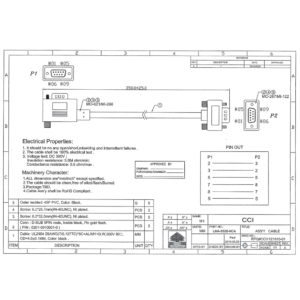

Compatible Cable designed and built a tooling approach to meet our client’s space limitations. After approval of the tooling specification, we presented our client with a CAD drawing of their cable, including the wiring diagram, electrical and mechanical characteristics, a comprehensive parts list, and a seal of RoHS compliance. Upon approval of the drawing, we produced first article samples of the new custom cable which met our client’s requirement.

The Result

This cable became a regular production item for one of our client’s best-selling systems.

Are you an environmental technology company needing help with cable assemblies?